Advancements in product development over the past decade are streamlining many of traditional construction processes and making specific tasks like waterproofing and resurfacing more efficient with faster installation times, less stages and faster drying times.

We live in an exciting era of building because we are seeing new product developments that are performing far beyond industry standards.

Worksites have never been more productive, more efficient, more profitable, more ecologically sustainable, safer and responsive to hazards. At SEMCO, we are excited to be a part of the innovative progress of the industry in Australia.

New construction technology is achieving things that no one thought was possible with unprecedented performance. For example, entrepreneurial microbiologists have recently developed self-healing bio-concrete that are already being used on new buildings and remedial works.

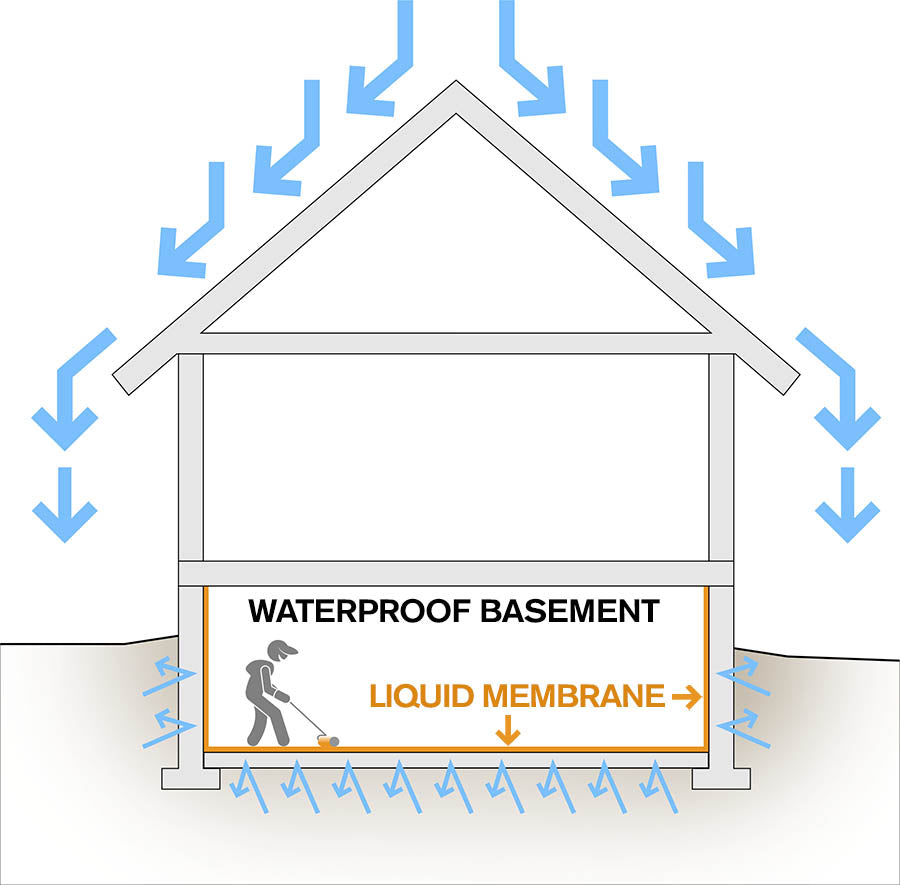

Since the emergence of water-based liquid membrane products in the waterproofing market during the 1990’s, there has been considerable performance advancements achieved from the fine-tuning and further engineering of waterproofing systems.

High Performance

SEMCO Liquid Membrane is one of the most advanced, high-performance waterproofing products on the market.

As a single component water-based liquid membrane it is comprised of an elastomeric fluid suspended with a copolymer adhesive.

With 400% elongation and anti-fracture properties, this revolutionary blend is engineered to streamline waterproofing needs through one high-performance solution.

Heavy duty and rated for load-bearing, SEMCO Liquid Membrane can withstand over 500 PSI pressure and up to 10 PSI of vapor transmission.

No Primer Required

The majority of waterproofing products and liquid membranes on the market require the use of specific branded or specified priming agents.

With SEMCO Liquid Membrane, the use of a primer is not necessary because it already contains the active copolymer adhesive needed to create bondage, which saves time and money on preparation.

Our hybrid blend provides integrated chemical adhesion enabling cross-linking to the applied surfaces, creating a bond for long lasting protection. We refer to this performance feature ‘Active Adhesion’ due to its exceptional adhesion to a variety of surfaces without the need for primers.

Our hybrid blend provides integrated chemical adhesion enabling cross-linking to the applied surfaces, creating a bond for long lasting protection. We refer to this performance feature ‘Active Adhesion’ due to its exceptional adhesion to a variety of surfaces without the need for primers.

Trialed, Tried and Tested

SEMCO Liquid Membrane passes Australia’s rigid Standards in flying colours. Not only that but it has been continuously tried and tested for decades on thousands of construction applications by professionals in the field.

“SEMCO Modern Seamless Surface engineers all if it products with one key factor, will it work in the field! As being one of the only manufacturers that is a contractor, we come across new obstacles related to long term product performance every day. Where other manufacturers place their trust in lab results, SEMCO invests in real-time field results. That’s the SEMCO difference” speaks Samel Sem, the Founder of SEMCO.

SEMCO Liquid Membrane is a result of over 30 years of devoted surface engineering in the United States of America.

For more information, click here to learn more about the Liquid Membrane.

Safer Products

Not only is new technology proving to increase the efficiency and productivity of construction processes but it is also proving to be safer.

SEMCO Liquid Membrane is Low VOC, meaning that it contains low amounts of volatile organic compounds, making it odourless, easier and safer to work with. Low VOC allows you to work with peace-of-mind that you are not inhaling toxic fumes and also allows for a fast drying time of 2 hours, enabling a speedier project completion.

Better for the Environment

The construction industry is one of the biggest consumers of natural resources and producers of waste and pollution.

The positive news is that there is growing awareness and action which is manifesting more environmentally responsible developments in construction technology products.

There is more emphasis on a global scale for businesses to not only talk about Corporate Social Responsibility but also reflect those values in their products and services.

Made with green materials, SEMCO Liquid Membrane is specifically designed to be more environmentally friendly. SEMCO Surfaces is committed to reducing our impact on the environment.

Easier to Use

SEMCO Liquid Membrane is easily applied to surfaces with a roller or brush. It is water-based so it is quick and easy to clean up. It does not require primer like other products on the market.

Applicable over cracks wider than 1/4", it stabilizes surfaces and also suppresses future cracks.

It can be applied to concrete, screeds, villaboard, compressed sheeting, plywood, stone, cladding and tiles.